The Future of Makerspaces: Cutting-Edge Innovations You Can Use by 2030

Makerspaces have always been at the forefront of creativity and technological innovation, but the next wave of advancements will take hands-on learning to a whole new level. By 2030, makerspaces will be more immersive, intelligent, and sustainable than ever before. The best part? Many of these technologies are already available or in development! Let’s explore five game-changing trends and the real-world products that are making them possible today.

1. AI-Driven Making: Your Personal Creative Assistant

AI is no longer just a futuristic idea—it’s already transforming how we design, prototype, and build. AI-powered tools can now generate 3D models, optimize engineering designs, and assist in coding projects with unprecedented precision. These intelligent assistants will work alongside makers, offering real-time suggestions, helping debug code, and even predicting design flaws before they happen.

For students and beginners, AI removes barriers by automating tedious tasks and simplifying complex design challenges. For experienced makers, AI can act as a powerful optimization tool, fine-tuning prototypes to be more efficient and cost-effective. The collaboration between human creativity and AI-driven efficiency will redefine what’s possible in makerspaces.

Tech to Watch:

Autodesk Fusion 360 with AI Generative Design – Uses AI to suggest optimal designs based on material and function constraints.

Fable AI from Creativity Inc. – Helps students and creators brainstorm ideas using natural language.

GitHub Copilot – AI-powered coding assistant that suggests and completes code in real-time.

By 2030, expect AI to be a core part of the makerspace experience, making creativity and technical expertise more accessible than ever.

2. Holographic & Mixed Reality Design: The End of Screens?

The way we interact with technology is evolving. Instead of designing on flat screens, makers will soon sculpt, assemble, and test prototypes in immersive 3D environments. Augmented reality (AR) and virtual reality (VR) will allow students to manipulate digital objects as if they were physical, making learning more engaging and intuitive.

With mixed reality tools, makers can test mechanics before ever building a physical model, refine designs through interactive overlays, and even collaborate in real time with teams across the world. This means faster iteration, fewer wasted materials, and a more hands-on approach to problem-solving—even in remote settings.

Tech to Watch:

Microsoft HoloLens 2 – Already used in industrial design and education to create mixed-reality prototypes.

Meta Quest 3 – Offers a highly immersive VR experience for CAD design and virtual prototyping.

Gravity Sketch – A VR-based 3D modeling tool allowing users to draw and design in mid-air.

By 2030, holographic workstations could replace traditional monitors, making the design process more fluid, collaborative, and accessible.

3. Sustainable Making & Biofabrication: Building with Nature

Makerspaces are becoming sustainability hubs, prioritizing materials and processes that minimize waste and reduce environmental impact. The future of making won’t just be about creating—it will be about creating responsibly.

Imagine growing your own materials instead of manufacturing them. Mycelium-based materials can replace plastics, algae can be used for renewable bioinks, and bacterial leather will offer an alternative to animal-based products. Schools and community makerspaces will also integrate recycling systems that transform waste into new materials, promoting a true circular economy.

Tech to Watch:

Mycelium-based building materials (MycoWorks, Ecovative) – Grown from fungi, these materials are biodegradable and used for construction and packaging.

Precious Plastic Machines – Open-source tools that allow makers to recycle plastic into new products.

Filabot & ProtoCycler – Devices that turn plastic waste into usable 3D printer filament.

By 2030, expect makerspaces to be equipped with biofabrication labs, giving students hands-on experience with sustainable innovation.

4. Self-Assembling & Programmable Materials: The Next Evolution of Fabrication

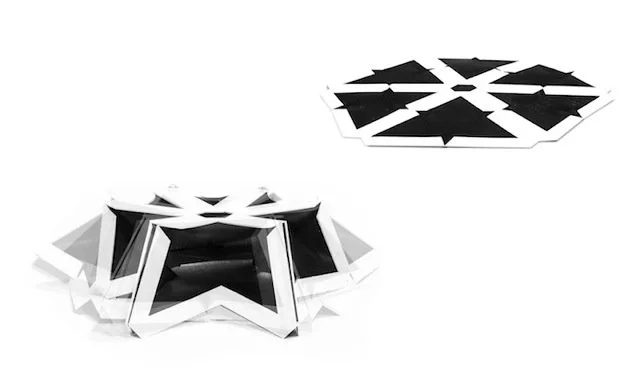

What if the objects you built could change shape, repair themselves, or respond to their environment? 4D printing is bringing this concept to life by creating programmable materials that shift over time based on external stimuli like heat, water, or light.

This technology will revolutionize multiple industries—from self-repairing infrastructure to adaptive clothing. In makerspaces, students could design structures that unfold themselves when exposed to sunlight or materials that change their properties in response to temperature. The ability to program physical materials will add a whole new dimension to hands-on learning.

Tech to Watch:

MIT Self-Assembly Lab – Developing materials that fold and shape themselves based on temperature, light, or water exposure.

Carbon 3D Printers – Uses digital light synthesis to create high-strength, flexible materials for shoes, medical devices, and more.

BASF 4D Printing Materials – Smart polymers that respond to external stimuli.

By 2030, programmable materials will be an everyday tool in makerspaces, offering endless opportunities for experimentation and innovation.

5. Wearable Technology & Brain-Computer Interfaces: The Ultimate Hands-Free Making

Imagine controlling a robot, designing a product, or coding a program—just by thinking. Brain-computer interfaces (BCIs) are making this possible, allowing users to interact with technology without the need for physical input. At the same time, wearable tech like haptic gloves will let makers “feel” virtual materials and interact with digital objects as if they were real.

For students with mobility impairments, this could make makerspaces more inclusive than ever. For everyone else, it could unlock a new level of precision and creativity, making the act of prototyping faster, more intuitive, and deeply immersive.

Tech to Watch:

OpenBCI – Brainwave-sensing headsets that allow users to control computers and machines with their thoughts.

HaptX Gloves – Provides realistic touch feedback for VR and remote-controlled robotics.

Tap Strap 2 – A wearable keyboard and mouse alternative that detects hand movements.

By 2030, wearable and brain-controlled technology will be a standard feature in makerspaces, redefining how we interact with the world of making.

Makerspaces of 2030: What’s Next?

As technology continues to evolve, makerspaces will remain at the intersection of creativity and innovation. Innovative tools will not only change how we create but also how we teach, collaborate, and solve problems.

Which of these technologies do you think will have the biggest impact? How do you see makerspaces evolving in the next decade? The future of making is unfolding now, and the best part is—we all get to be a part of it.

If you’re looking to bring cutting-edge makerspace experiences to your school or organization, our comprehensive curriculum and consulting services can help you integrate these emerging technologies into your learning environment. Contact us to learn how we can support your makerspace journey!

DO YOU WANT TO KNOW WHAT TECH IS RIGHT FOR YOUR SCHOOL?

If you’re looking to bring cutting-edge makerspace experiences to your school or organization, our comprehensive curriculum and consulting services can help you integrate these emerging technologies into your learning environment.

Contact us to learn how we can support your makerspace journey!